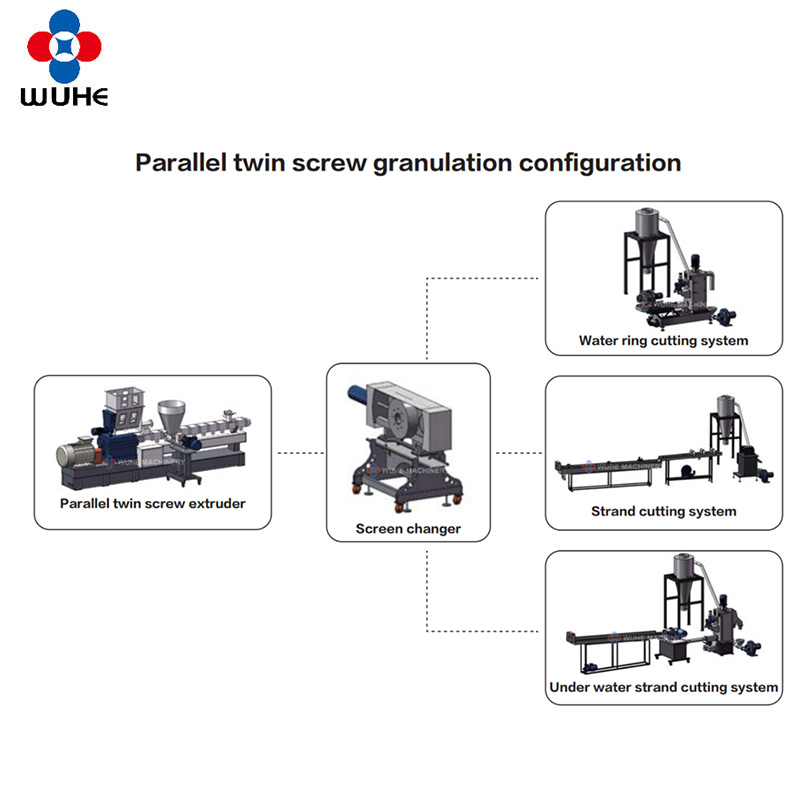

Filler caag ah oo isbarbar socda dib u warshadaynta iyo mishiinka khadka granulation

Halbeegga ugu muhiimsan

Raadiyaha furka

● Waxay la mid tahay hopper quudinta extruder si loo xaqiijiyo xakamaynta tooska ah.

Quudiye

● Maaddada hopper: birta aan-ahma lahayn; Habka quudinta: Quudinta quudinta; Xakameeyaha Qudeeyaha: Waxaa maamula beddelka.

Mashiinka soo saarista

● Furaha iyo dhululubada waxay qaataan qaab-dhismeedka "dhismaha", kaas oo leh is-beddel wanaagsan oo loo isticmaali karo isku-dhafka kasta iyadoo loo eegayo farsamooyinka farsamaynta walxaha kala duwan; Silindu waxay ka samaysan tahay birta nitrided iyo walxo bimetallic ah, kuwaas oo u adkaysta xidhashada iyo.

● Iska caabbinta daxalka iyo nolosha adeegga oo la dheereeyey; Qaybaha duntu waxay ka samaysan yihiin bir nitrided ah iyo qalab bir ah oo degdeg ah, iyo curyaaminta waxaa loogu talagalay naqshadeynta kombuyuutarka, oo ay weheliyaan farsamooyin farsamaysan oo gaar ah, si loo hubiyo in ilkaha caadiga ah ee qaybta shaqada ee dunta ah.

● Nadiifinta dusha sare iyo is-nadiifinta wanaagsan; Habka isku xirka gaarka ah ee loo qaabeeyey iyo aaladda gudbinta waxay kor u qaadaysaa xoogga qaybaha dunta leh iyo ulaha xudunta u ah, gaaritaanka kala-baxa walxaha isku midka ah, isku-dhafka wanaagsan iyo saamaynta balaastiga, iyo cufnaanta walxaha.

● Ujeedada wakhtiga haynta gaaban iyo hufnaanta gudbinta sare.

Shaashada beddelka

● Beddelayaasha shaashadaha kala duwan waxay daboolaan baahida macaamiisha kala duwan.

Waxaan inta badan leenahay saddex nooc oo ah habka goynta pellets:

1. Nidaamka goynta giraanta biyaha.

2. Nidaamka goynta strand.

3. Habka goynta strand biyaha hoostooda.

Iyada oo ku saleysan sifooyinka walxaha kala duwan, waxaan kugula talineynaa hababka goynta kala duwan.

1. Nidaamka goynta giraanta biyaha

● Nidaamka goynta wuxuu qaataa giraanta biyaha madaxa dhimista extrusion si loo gooyo, taas oo hubin karta muuqaalka saxda ah ee qayb ka mid ah.

Mashiinka biyo-saareeynta Centrifugal

● Mashiinkaani wuxuu leeyahay faa'iidooyin badan, sida fuuq-bax aad u sarreeya, isticmaalka tamarta yar, waxtarka sare, heerka sare ee otomatiga, wuxuuna aad u yareeyaa xoogga shaqada. Fuuqbaxa waa nadiif, sidoo kale waa laga dhaqi karaa ciidda yar yar iyo noocyada yaryar ee plaska.

2. Nidaamka goynta Strand

● Qalabka qaarkood ee leh viscosity sare, sida PP, waxaan kugula talineynaa inaad isticmaasho habka wax lagu gooyo.

Nidaamka goynta taagan biyaha hoostooda

● Ku habboon alaabta dhalaalaysa, sida PET iyo PP iyo wixii la mid ah.

● Dhuumaha hawada oo qalajiya

Biyaha ku jira dusha sare ee pellets waxay ku soo baxaan iyada oo loo marayo mabda'a gudbinta dhuumaha hawada, waxayna u raraan pellet-ka qallalan meesha wax lagu ururiyo, ka dibna daawaynta la socota.

Nidaamka xakamaynta korantada

● PLC kontorool toos ah

jaantuska agabka